TCalcite powder manufacturing process typically involves several stages, from extraction to processing and packaging.

Here's an overview of the typical steps involved:

1. Extraction and Mining

l Mining: Calcite is extracted from natural mines. It is found in the form of marble or limestone, which are forms of calcium carbonate (CaCO₃).

l Blasting and Excavation: The calcite is often extracted through blasting, which involves using explosives to break up the rock.

2. Crushing

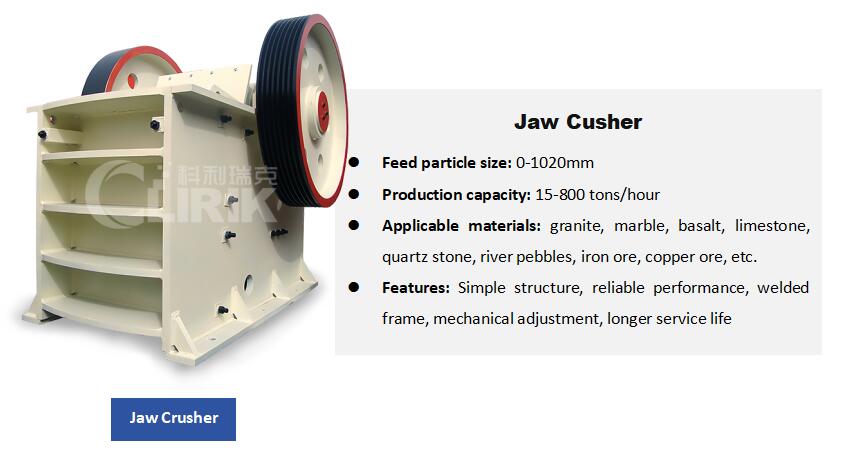

l Primary Crushing: The extracted calcite rocks are fed into primary crushers (e.g., jaw crushers) to break them into smaller chunks.

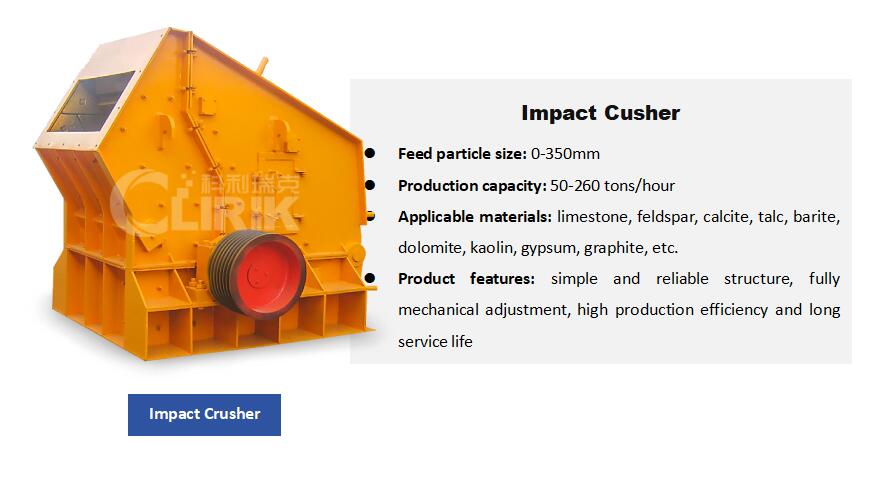

l Secondary Crushing: The smaller chunks are then passed through secondary crushers (e.g., impact crushers or cone crushers) to reduce them to even finer particles.

3. Grinding

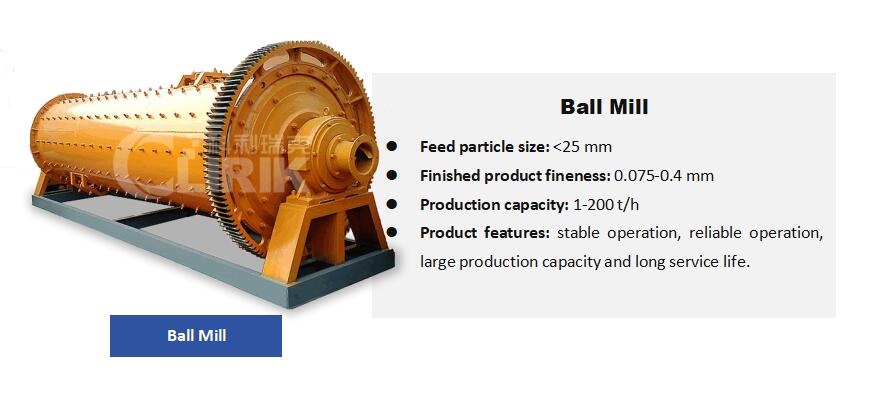

l Ball Mill/Vertical Roller Mill: The crushed calcite is then ground into fine powder using grinding mills. Ball mills or vertical roller mills are typically used in this process.

l Grading and Screening: The ground material is passed through sieves and classifiers to obtain uniform particle size. This step ensures the powder is of the desired fineness.

4. Coating (Optional)

l Surface Modification: Sometimes, the calcite powder is coated with a thin layer of stearic acid or other surface modifiers to enhance its properties for specific applications, such as in plastics or paints.

5. Drying (Optional)

l Dryers: The purified calcite powder is then dried using rotary dryers or other types of dryers to reduce moisture content.

6. Packaging

l Packaging Machines: The dried calcite powder is then packed into bags or bulk containers using automated packaging machines.

Quality Control

l Testing: Throughout the process, samples are taken for quality testing to ensure that the final product meets industry standards and customer specifications.

Applications

Calcite powder has various applications, including:

l Construction Industry: As a filler material in concrete and asphalt.

l Plastic Industry: As a filler to improve the physical properties of plastics.

l Paints and Coatings: As an extender and to provide a smooth finish.

l Paper Industry: As a filler to improve the brightness and opacity of paper.

l Agriculture: As a soil conditioner and animal feed additive.

Environmental Considerations

l Dust Control: Measures are taken to control dust during the manufacturing process to protect workers and the environment.

l Waste Management: Proper management of mining and processing waste is crucial to minimize environmental impact.

By following these steps, manufacturers can produce high-quality calcite powder suitable for various industrial applications.